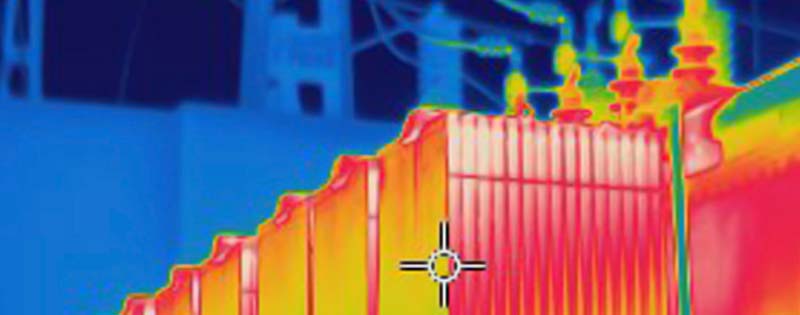

Infrared Inspections

At Global Power Group, Inc., our infrared inspections focus on providing a non-contact, non-destructive solution for testing your electrical systems. With our electrical preventive maintenance programs, we consistently test your systems for excess heat on connectors, conductors or components that could cause potential problems. This proactive approach minimizes down time and mitigates damages.

What we do!

Our certified electricians are also trained thermographers and use state of the art equipment and proactive technologies and services to determine when a failure or outage may occur.

Types of Equipment We Work On

- Transformers

- Relay Panels

- Fuse Disconnects

- Circuit Breakers

- Switchgear

- Fans for Bearing Degradation

- AC & DC Capacitor Banks

- Harmonic Filters for Capacitor Degradation

- Batteries to Detect Thermal Runaway

Infrared testing is more efficient to find simple as well as dangerous electrical system trouble spots before they become disastrous. With a thorough analysis of the data we collect, we see patterns emerge that help us to address minor issues before they become major ones.

Benefits of performing regular infrared inspections:

- Elimination of unplanned outages

- Risk Assessment/Management

- Optimized Capital Expenditures

- Improved system reliability

- Increased availability due to greater reliability of the equipment

- Planned maintenance vs. Reactive

- Reduced cost of maintenance and labor

- Assurance of initial equipment installation

- Reduced likelihood of a catastrophic failure

- Improved worker safety and operating efficiency

- Reduced capital costs by extending the life of plant assets

& increasing availability - Deferred or avoided capital costs for added capacity

- Minimized scheduled outages – Extending time between outages